Abbreviation for American Wire Gauge.

Designation for appliance wiring material.

Electric current that continually reverses its direction. It is expressed in cycles per second (hertz of Hz).

The temperature of a medium (gas or liquid) surrounding the object.

A standard system for designating wire diameter. Also referred to as the Brown and Sharpe (B&S) wire gauge.

(See Current Carrying Capacity).

The unit of current. One ampere is the current flowing through one ohm of resistance at one volt potential.

Relief of mechanical stress through heat and gradual cooling. Annealing copper renders it less brittle.

The range of frequencies audible to the human ear. Usually 20-20,000 Hz.

A commonly used industry term for partial surge protection, usually a single MOV protecting line-to-neutral (see Full Protection).

A fibrous or metallic group of filaments interwoven in cylindrical form to form a covering over one or more wires.

The voltage at which the insulation between conductors breaks down.

A group of wires of the same diameter twisted together without a predetermined pattern.

The twisting together of two or more insulated conductors to form a cable.

The ability of a dielectric material between conductors to store electricity when a difference of potential exists between the conductors. The unit of measurement is the farad, which is the capacitance value that will store a charge of one coulomb when a one-volt potential difference exists between the conductors. In AC, one farad is the capacitance value that will permit one ampere of current when the voltage across the capacitor changes at a rate of one volt per second.

The complete path of an electrical current. When the continuity is broken, it is called an open circuit; when continuity is maintained, it is called a closed circuit.

To hold the current or voltage at a specific fixed level.

Permanent deformation of the insulation due to mechanical force or pressure (not due to heat softening).

A system for circuit identification through use of solid colors and contrasting tracers.

An insulating or jacketing material made by mixing two or more ingredients.

In a wire or cable, the measurement of the location of the center of the conductor with respect to the geometric center of the surrounding insulation.

An insulated wire suitable for carrying electrical current.

The parts of the connector that actually carry the electrical current, and are touched together or separated to control the flow.

A test to determine whether electrical current flows continuously throughout the length of a single wire or individual wires in a cable.

A flexible insulated wire.

Ionization of air surrounding a conductor caused by the influence of high voltage. Causes deterioration of insulation materials.

The minute cracks on the surface of plastic materials.

Abbreviation for Canadian Standards Association, a non-profit, independent organization that operates a listing service for

electrical and electronic materials and equipment. The Canadian counterpart of the Underwriters Laboratories.

The maximum current an insulated conductor can safely carry without exceeding its insulation and jacket temperature limitations.

The voltage that an insulation can withstand before breakdown occurs. Usually expressed as a voltage gradient (such as volts per mil).

The capacitance measured directly from conductor to conductor through a single insulating layer.

An electric current that flows in only one direction.

In a cable, the uninsulated wire laid over the component or components and used as a ground connection.

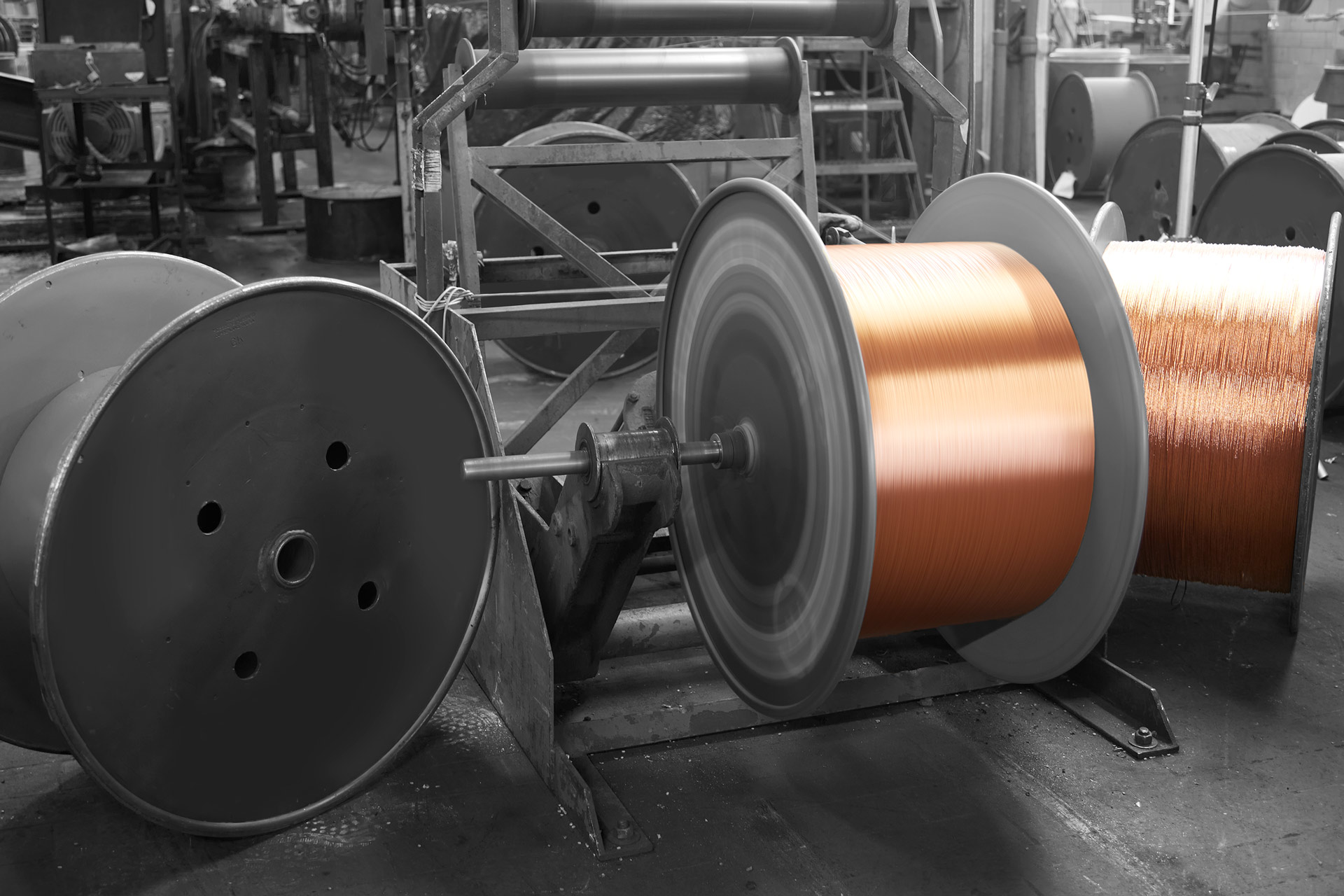

In wire manufacture, pulling metal through a die or series of dies to reduce diameter to a specified size.